嘉宾介绍

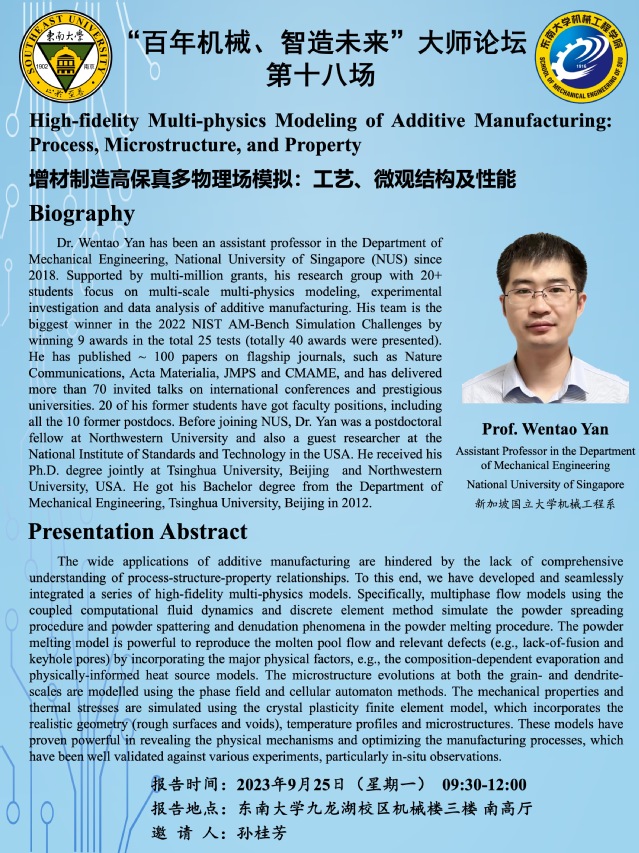

Dr. Wentao Yan has been an assistant professor in the Department of Mechanical Engineering, National University of Singapore (NUS) since 2018. Supported by multi-million grants, his research group with 20+ students focus on multi-scale multi-physics modeling, experimental investigation and data analysis of additive manufacturing. His team is the biggest winner in the 2022 NIST AM-Bench Simulation Challenges by winning 9 awards in the total 25 tests (totally 40 awards were presented). He has published ~ 100 papers on flagship journals, such as Nature Communications, Acta Materialia, JMPS and CMAME, and has delivered more than 70 invited talks on international conferences and prestigious universities. 20 of his former students have got faculty positions, including all the 10 former postdocs. Before joining NUS, Dr. Yan was a postdoctoral fellow at Northwestern University and also a guest researcher at the National Institute of Standards and Technology in the USA. He received his Ph.D. degree jointly at Tsinghua University, Beijing and Northwestern University, USA. He got his Bachelor degree from the Department of Mechanical Engineering, Tsinghua University, Beijing in 2012.

讲座摘要

The wide applications of additive manufacturing are hindered by the lack of comprehensive understanding of process-structure-property relationships. To this end, we have developed and seamlessly integrated a series of high-fidelity multi-physics models. Specifically, multiphase flow models using the coupled computational fluid dynamics and discrete element method simulate the powder spreading procedure and powder spattering and denudation phenomena in the powder melting procedure. The powder melting model is powerful to reproduce the molten pool flow and relevant defects (e.g., lack-of-fusion and keyhole pores) by incorporating the major physical factors, e.g., the composition-dependent evaporation and physically-informed heat source models. The microstructure evolutions at both the grain- and dendrite- scales are modelled using the phase field and cellular automaton methods. The mechanical properties and thermal stresses are simulated using the crystal plasticity finite element model, which incorporates the realistic geometry (rough surfaces and voids), temperature profiles and microstructures. These models have proven powerful in revealing the physical mechanisms and optimizing the manufacturing processes, which have been well validated against various experiments, particularly in-situ observations.

讲座时间:2023年9月25日 9:00(GMT+08:00)

讲座地点: 东南大学机械楼南高厅

主办单位:东南大学机械工程学院